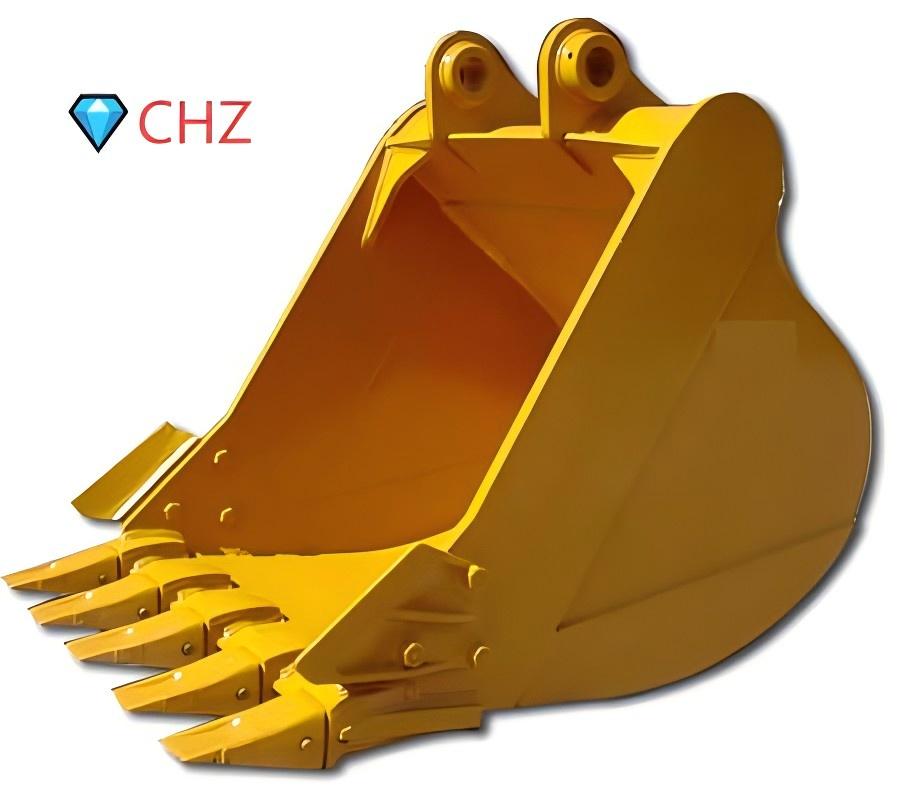

CHZ Custom Excavator Bucket Solutions

In the construction, mining, and agriculture industries, the performance of heavy machinery is only as strong as its attachments. Among these, the PC200 Excavator Bucket stands out as one of the most essential tools for digging, loading, and material handling. As a top-tier Excavator Bucket Manufacturer, CHZ has earned a strong reputation for producing high-strength, wear-resistant buckets that enhance productivity and durability across diverse job sites.

Based in China, CHZ is recognized among manufacturers for its advanced engineering, precision manufacturing, and commitment to quality. The company specializes in crafting Heavy-Duty Excavator Digging Buckets designed specifically for Komatsu PC200 series machines—ensuring perfect compatibility, optimal weight balance, and superior digging force.

What sets CHZ apart as a Custom Earthmoving Bucket Supplier is its ability to tailor products to meet unique customer needs. Whether modifying bucket geometry for specialized terrain, upgrading materials for abrasive conditions, or integrating quick coupler systems for multi-functionality, CHZ offers full custom design services that allow clients to optimize equipment performance. This level of adaptability makes the brand a trusted partner for construction firms, rental companies, and OEMs worldwide.

Each PC200 Excavator Bucket produced by CHZ is built using high-tensile structural steel and reinforced with wear-resistant liners and cutting edges. These features significantly extend service life, reduce maintenance costs, and improve overall efficiency—especially in demanding applications such as quarrying, trenching, and land clearing.

As a professional Excavator Bucket Manufacturer, CHZ follows strict production protocols to ensure every unit meets international quality standards. Advanced CNC machining, robotic welding, and automated painting lines are employed throughout the manufacturing process to guarantee dimensional accuracy, structural integrity, and corrosion resistance.

All CHZ products are developed and tested in state-of-the-art facilities located in China, where engineers work closely with field technicians to simulate real-world working conditions. This ensures that each Heavy-Duty Excavator Digging Bucket delivers maximum performance under pressure—whether in rocky terrain, muddy environments, or large-scale infrastructure projects.

Beyond standard offerings, CHZ also develops custom earthmoving buckets for niche applications such as forestry, demolition, and marine excavation. These specialized solutions often include features like extended side cutters, replaceable teeth, and anti-slip bottom plates—enhancing functionality while improving operator safety and efficiency.

Sustainability and resource optimization are core values at CHZ. The company actively incorporates eco-friendly practices into its operations, including material recycling, energy-efficient manufacturing, and long-life component design—all aimed at reducing environmental impact without compromising strength or reliability.

Looking ahead, CHZ continues to invest in innovation, expanding its product line to support next-generation excavators and evolving industry demands. With ongoing research into lightweight materials, smart attachment integration, and modular bucket systems, the brand is well-positioned to lead in the future of earthmoving technology.

In conclusion, CHZ exemplifies excellence among manufacturers in China offering custom excavator bucket solutions that combine power, precision, and longevity. By focusing on tailored engineering, rigorous quality control, and customer-driven innovation, CHZ delivers high-performance attachments that elevate machine capability and project outcomes. For businesses seeking premium, branded PC200 Excavator Buckets, CHZ is the ideal partner for lasting value and operational success.